- Company

- Performance

- Solutions

- Products

- Service

- Career

- Contact

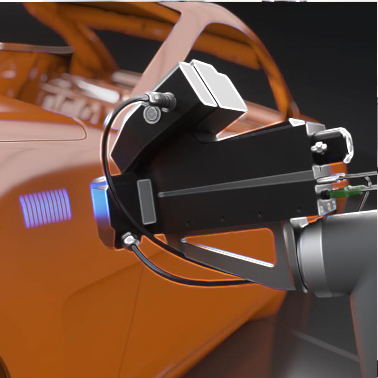

Continuous flexibility that doesnt require any breaks: The robot used represents the core of your project. It can be expanded and connected with a wide variety of components. Exactly according to your ideas, we can optimally program the robot's operational sequences in order to find a solution for every problem.

Defects and errors can be detected in a simple yet efficient way thanks to the fully automated optical inspection of test objects. Among other things, a presence or variant check of the different parts can be carried out here, including gap measurements or color recognition with possible color deviations. Different paintwork or leather coverings can also be checked and recognized without any problems.

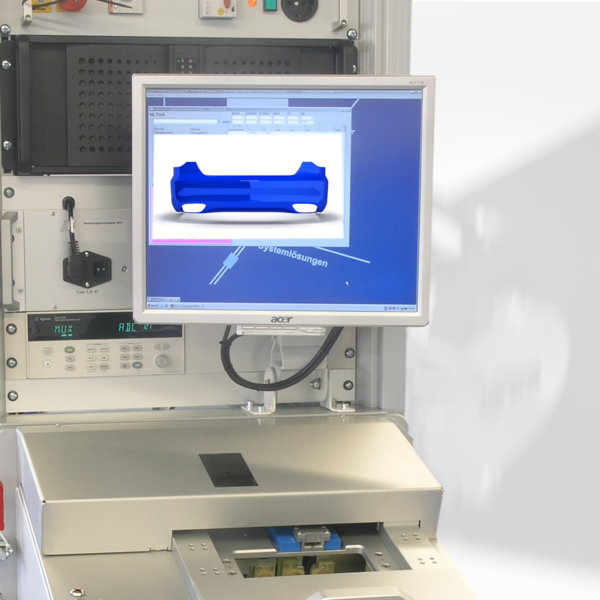

Going a step further than optical control would be a two- or even three-dimensional scan. Similar to optical control, deviations can be detected, measured and optically displayed. This means that gap measurements can be carried out even more precisely, and components can be checked for the correct installation position.

Tests like these are becoming increasingly relevant, especially for future technologies such as autonomous driving. In this way, the functionality and the resulting active safety can be guaranteed. With the correctly set parameters, these test procedures are not a challenge for the RoboInspector, which significantly simplifies integration into existing process flows.

A test variant that can currently only be operated with great effort is the paint layer thickness measurement of one or more layers of painted parts such as bumpers. Without this measuring method, non-destructive testing is almost impossible. The test can also be used for large quantities to help reduce rejects, which, in contrast to random samples, enables a 100% test rate. With the help of the RoboInspector, a measurement is carried out quickly, accurately and without damage, which means that environmental aspects are taken into account in addition to time and quality requirements.

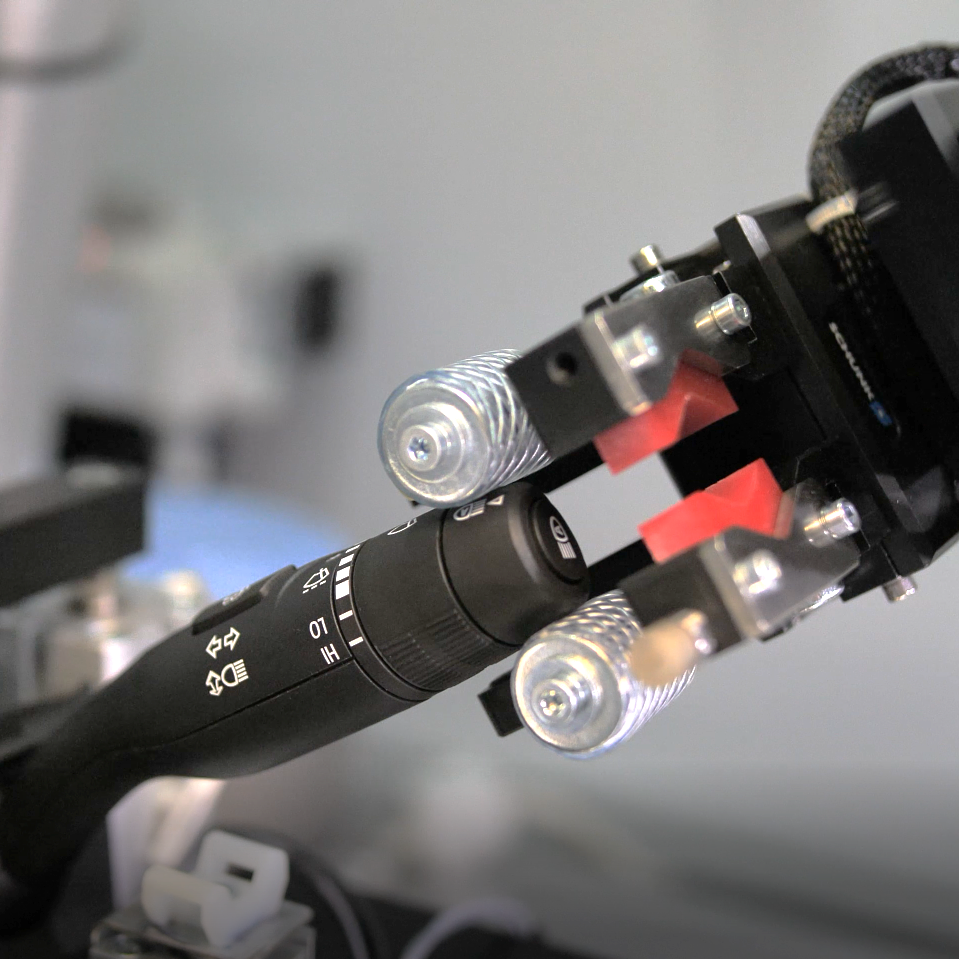

In addition to the optical tests, there is also the possibility to test different parts for mechanical properties, such as haptic tests. The product is fully automatically inspected and tested for possible deviations. Tested functional Parts can then be used for further processing, while defective parts can be sorted out directly. This saves time and prevents possible complaints at an early stage.

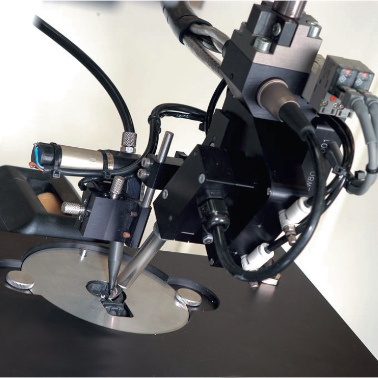

Another option is to use the robot for machining and assembly work, such as drilling, milling, soldering, screwing or sticking. If required, the automatic helper can also be programmed to carry out tasks in parallel with those of a potential employee, for example by fitting clips or smaller components while unscrewing panels at the same time.