- Company

- Performance

- Solutions

- Products

- Service

- Career

- Contact

Lighting inspection technology allows to detect even the smallest defects. Just like our other solutions, all test systems in the area of ambient light testing are modular, which allows for precise individualization according to your requirements.

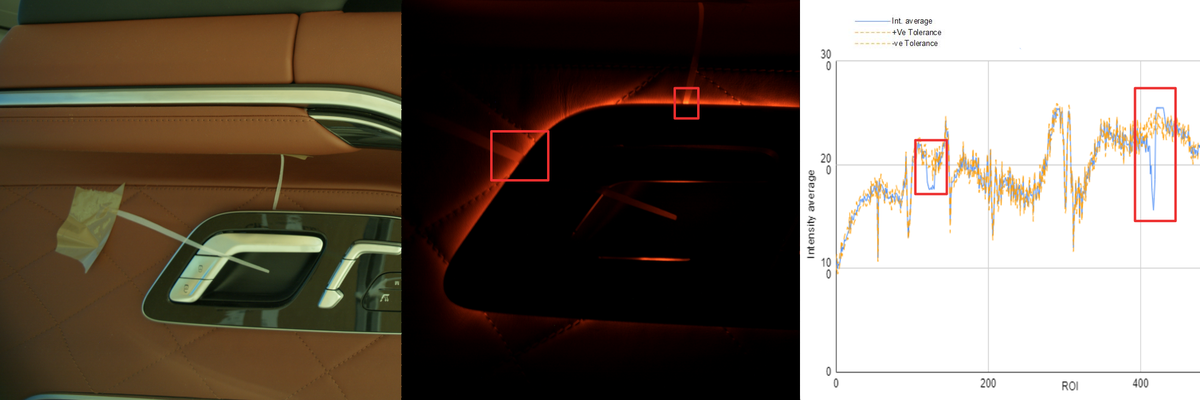

Simulation of a tiny surface defect under direct lighting: Although the crack (50 µm) is barely visible to the human eye, we can detect the defect with the help of our inspection technology.

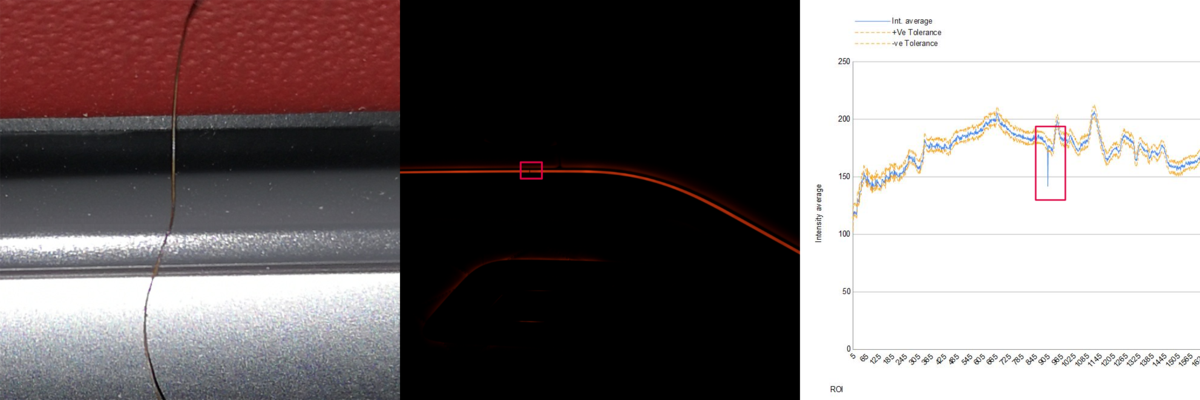

Simulation of a transparent contamination with indirect lighting: A simulated foreign body, which selectively weakens the light intensity and at the same time creates an unpleasant scattered light, can be filtered out during the test process and displayed in the diagram.