- Company

- Performance

- Solutions

- Products

- Service

- Career

- Contact

Lean production (or lean manufacturing) describes a systematized production organization that focuses on streamlining manufacturing systems while maximizing productivity. To do this, the OEE (Overall Equipment Effectiveness) must first be determined. This consists of:

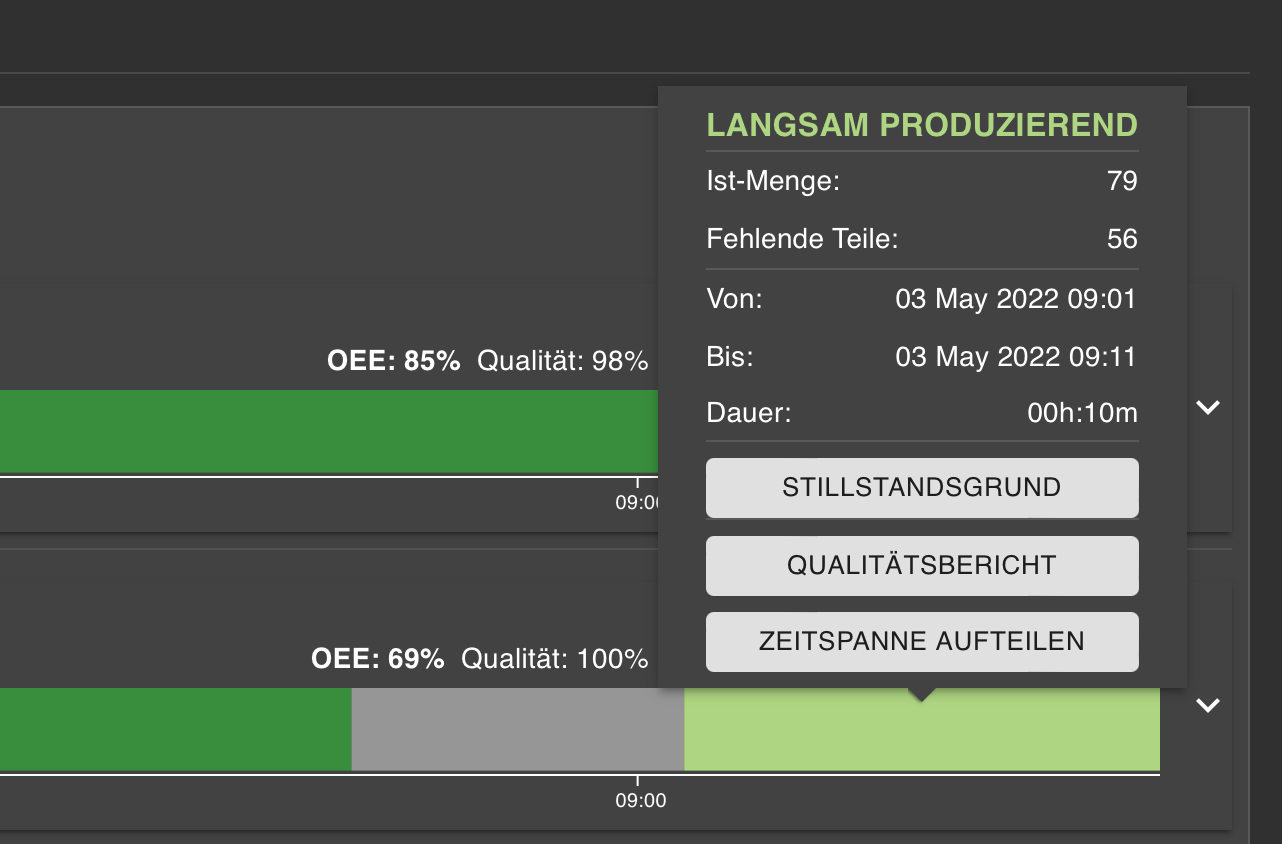

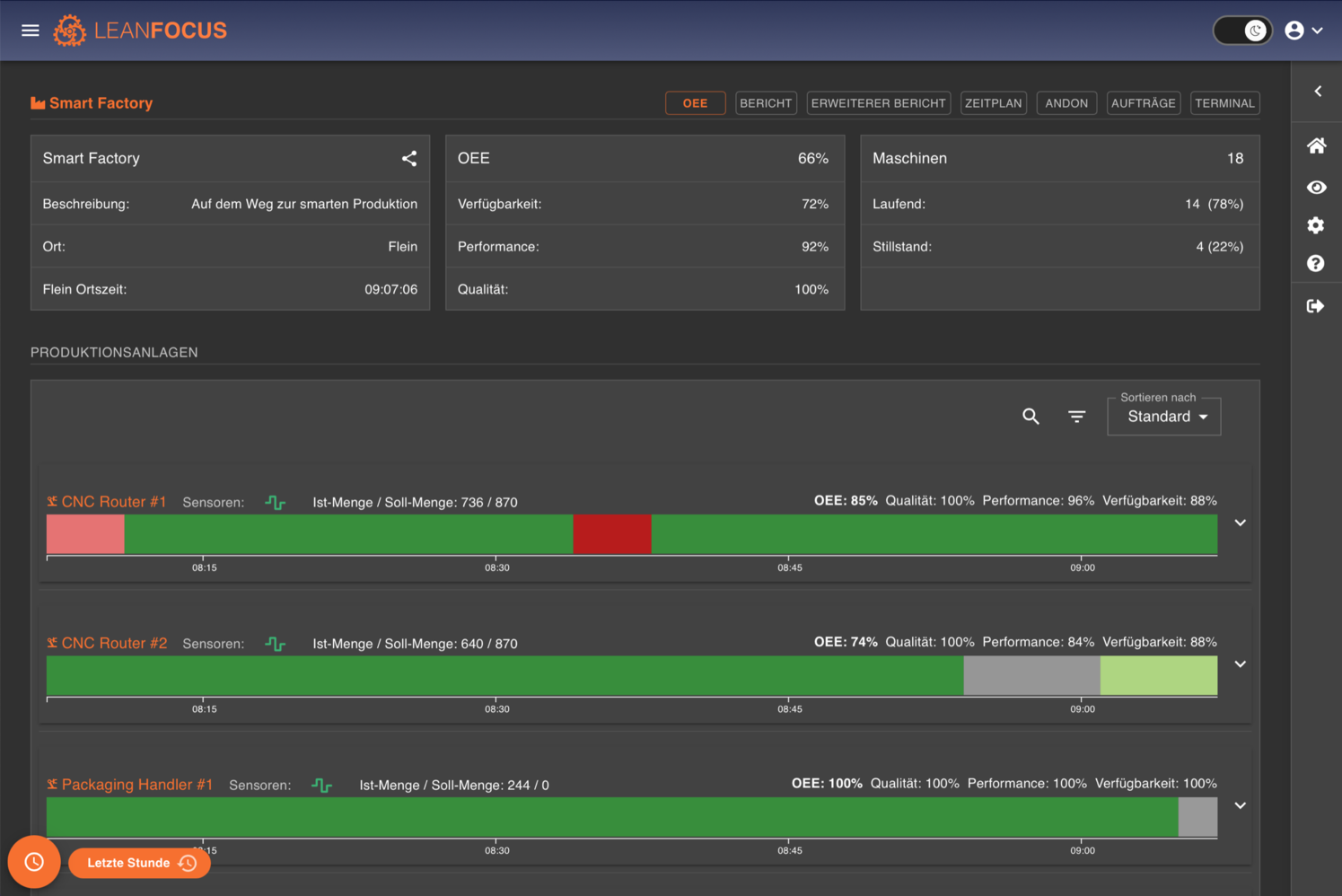

Process monitoring describes an essential component for the optimization of work processes. An analysis of different KPIs (Key Performance Indicators) such as duration, costs or sustainability is carried out. On the one hand, this allows the quality of a process to be defined and, on the other hand, bottlenecks or weak points can be specifically identified and targeted. However, the adjustments that can be made afterwards vary greatly depending on the company and its goals, which is why an individual solution is required. At this point we offer LEANFOCUS, a pragmatic and

uncomplicated solution for your company. With the help of the simple conversion and implementation, tangible information about your production performance can be determined within 24 hours. Important key figures can be documented with minimal effort. Thanks to the IoT application, these can be checked up at any time, regardless of location, on any Internet-enabled device. Whether you want to focus on a single station or the entire production line is entirely up to you. Thanks to the researched key figures regarding availability, performance and quality,

the so-called "Overall Equipment Effectiveness" (OEE) can be calculated. This value provides information about the proportion of the planned machine runtime that was actually produced in accordance with the quality criteria. Based on the OEE, actions can then be planned to further optimize the process quality. Within this framework, KMPC Innovations ensures the supply and further development of LEANFOCUS, tailored to your needs, while we provide the associated hardware as well as its maintenance and integration.

LEANFOCUS enables you to transfer existing manual and automated production to Industry 4.0 at low cost. Which aspects of your production should be improved depends entirely on your individual wishes. The key figures collected can be used, for example, for:

KMPC Innovations GmbH supports customers with digitization projects and the systematic development of innovative services and products based on current technologies. Thanks to the experience from national and international digitization projects in various business areas and industries as well as the proximity to research and industry, KMPC Innovations provides a valuable transfer of knowledge and accompanies customers on the way from analysis to finding a solution to implementation.