- Company

- Performance

- Solutions

- Products

- Service

- Career

- Contact

The key point of the test is the connector or socket of the cable harness that is designed by the manufacturer for a very limited number of connection cycles.

For this reason, the necessary counterpart, our contacting adapter, is of central importance for this application to guarantee a reliable and sustainable test.

If the timeframe is tight and initial test results are required quickly, there is usually only one option: temporary and fast adaption of the DUT harness. This solution with a limited number of connection cycles can be used to bridge the period until completion of the final contacting adapter.

Vehicle manufacturers use one or several vehicle connection points on the cable harness for power supply and communication. There are several electronic components inside.

Headlight cleaning systems or cleaning nozzles for cameras are used to remove dirt and foreign bodies. These components are tested in a pneumatic test. Here we use self-sealing hose or hose connector variants.

Cameras with a KOAX interface often have a separate connection point that differs according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

Cameras with a LVDS interface often have a separate connection point that differs completely according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

Cameras with an Ethernet interface often have a separate connection point that differs completely according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

In the case of various electrical components, such as lighting elements, often no separate cable harness is installed, instead they are connected directly to the cable harness of the car body. These components also need to be contacted directly.

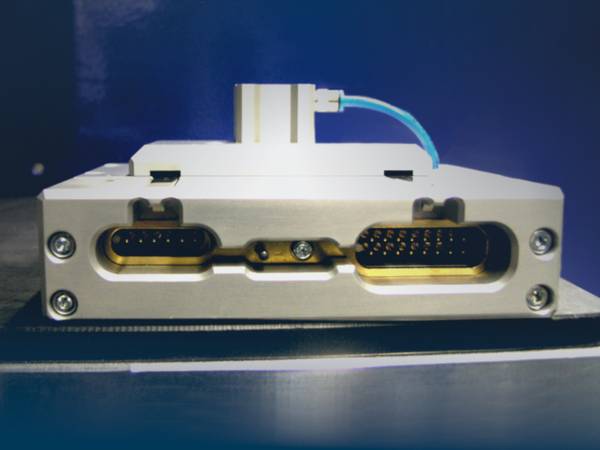

In industrial environments, simple, ergonomic and durable interfaces between test pieces and test equipment are required. The solid hard-anodised housing that has proven itself in industrial applications offers protection in heavy-duty environments and also ensures reliable connector guidance and testing. The connection point is locked by means of a spring-mounted latch throughout the entire test process so that the spring-mounted contact and switch contact pins can guarantee damage-free connection of the cable harness on the vehicle side. The gold-coated contact pins are designed for a high number of connection cycles and can be simply unscrewed and replaced if required. These contacting adapters can also be designed to meet special customer requirements, e.g. with 2 or 4-point contacts.

Vehicle manufacturers use one or several vehicle connection points on the cable harness for power supply and communication. There are several electronic components inside.

Headlight cleaning systems or cleaning nozzles for cameras are used to remove dirt and foreign bodies. These components are tested in a pneumatic test. Here we use self-sealing hose or hose connector variants.

Cameras with a KOAX interface often have a separate connection point that differs according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

Cameras with a LVDS interface often have a separate connection point that differs completely according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

Cameras with an Ethernet interface often have a separate connection point that differs completely according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

In the case of various electrical components, such as lighting elements, often no separate cable harness is installed, instead they are connected directly to the cable harness of the car body. These components also need to be contacted directly.

Every second counts if the test time and the associated cycle time need to be as short as possible. Our automatic contacting process can help here because, after a successful test by the system, it independently unlocks and ejects the connection point pneumatically or electrically. The operator or the automatic handling system can remove the test piece immediately.

Like the manual contacting adapter, the other properties of the automatic contacting adapter also meet our high standards. This includes the hard-anodised housing for reliable connector guidance, a spring-mounted latch for locking, and gold-plated, spring-mounted and screwed contact and switch contact pins that guarantee damage-free connection and a high number of connection cycles. These contacting adapters can also be designed to meet special customer requirements, e.g. with 2 or 4-point contacts.

Vehicle manufacturers use one or several vehicle connection points on the cable harness for power supply and communication. There are several electronic components inside.

Headlight cleaning systems or cleaning nozzles for cameras are used to remove dirt and foreign bodies. These components are tested in a pneumatic test. Here we use self-sealing hose or hose connector variants.

Cameras with a KOAX interface often have a separate connection point that differs according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

Cameras with a LVDS interface often have a separate connection point that differs completely according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

Cameras with an Ethernet interface often have a separate connection point that differs completely according to the communication type and camera type. Here special details, e.g. precisely defined cable shields, contact resistances, special connectors or other special factors, need to be observed.

In the case of various electrical components, such as lighting elements, often no separate cable harness is installed, instead they are connected directly to the cable harness of the car body. These components also need to be contacted directly.